The term “heating elements” refers to any and all heat generation equipment in electric heaters. Found in equipment of all shapes and sizes and with a variety of configurations and materials, heating elements all have the same goal: to convert electrical energy into heat energy up to 1300°F, and then distribute said heat energy through or to solids, liquids or gases (including air) via convection, conduction or radiation. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

Ulanet™ has 78 years of engineering and manufacturing experience in the production of cartridge, hermetically sealed, miniature, capsule, industrial thermostats, thermal time delay relays, immersion heaters, and numerous other heating elements.

At Hi-Heat Industries, we understand that every industrial application is unique, and our commitment to customization sets us apart from the competition. Alongside our standard product offerings, we provide various customization options to tailor the heating elements precisely to the client's specifications. These options include temperature controls, bonding methods, and private labeling.

Thermo Heating Elements is the world-wide leader in manufacturing flexible heating elements of the highest quality. Our products include polymer thick film heaters, silicone heaters, tubular heaters, optically clear heaters, ultraflex heaters, mica heaters, kapton heaters, and pantograph heaters.

Dalton Electric Heating Co., founded in 1921, is a manufacturer of Watt-Flex high performance cartridge heaters. The unique split sheath design expands in a bore for maximized heat transfer. Dalton also manufactures replacement vacuum diffusion pump heaters for nearly all domestic and foreign pumps.

More Heating Elements Manufacturers

Applications

Heating elements find a wide range of applications across various appliances and industrial settings, where controlled and efficient heat generation is essential. In household appliances, such as electric heaters and hair dryers, heating elements are employed to produce warm air, providing comfort during cold weather or aiding in hair styling. Soldering irons, meanwhile, utilize heating elements to melt solder and join electronic components. In showers and water heaters, heating elements warm up the water for bathing or domestic use. Stoves additionally use heating elements to cook food by providing a consistent heat source for the cooking surface or oven. Furthermore, toasters use heating elements to quickly brown and crisp bread slices. Finally, clothes dryers rely on heating elements to dry wet laundry efficiently.

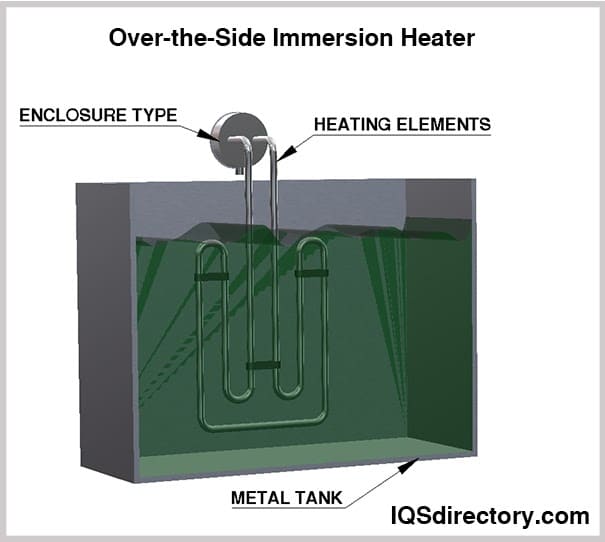

In industrial and commercial settings, heating elements also play a crucial role in numerous applications. For instance, in diffusion pumps, these elements assist in creating a vacuum by heating a vaporizable substance, which subsequently drives gas molecules out of the chamber. Kilns and furnaces employ heating elements to reach high temperatures for processes like pottery firing or metal smelting. Moreover, stainless steel liquid immersion heaters are widely used in industrial processes where liquids, such as water or chemicals, need to be heated. These immersion heaters consist of heating elements enclosed in a sheath, allowing them to be directly immersed in the liquid to efficiently transfer heat.

Overall, heating elements are fundamental components across various appliances and industrial applications, providing reliable heat generation, precise temperature control, and enhancing efficiency in a wide array of everyday and specialized processes.

The History of Heating Elements

In 1879, Thomas Edison used a carbon filament to light his incandescent light bulb. Because this filament also generated heat, he has received the credit of inventing the first heating element. However, we did not begin using elements such as these specifically for heat generation until the next century. We did, however, work on forms of heating.

The process by which heating works was first described and developed as the first law of thermodynamics in the late 19th century, by Julius Robert Mayer and James Prescott Joule. Soon after, the inventors of the age began applying thermodynamics in order to create heating elements. For example, in 1868, a painter from London, Benjamin Waddy Maughan, developed the first gas water heater. However, because it did not have a ventilation system with which to disperse vapors, it was not safe for home use. 21 years later, Edwin Ruud, a Norwegian-American, invented the first electric water heater, which worked much better.

One of the earliest discovered heating elements still used today is silicon carbide. It was discovered in 1891 by American inventor Edward G. Acheson, who discovered it by accident when trying to synthesize diamonds. What he got instead was one a synthetic material that is extremely hard, and perfect for high temperature applications and semiconducting. The next decade, in 1905, Albert Marsh discovered NiChrome (chromel). Because NiChrome can reach temperatures 300 times hotter than the competing heating elements of the time, it revolutionized the industry. In 1906, Marsh patented his discovery. Just three years later, General Electric began selling the first successful electric toaster, using NiChrome. Not long after, manufacturers electrified tea kettles. First, they had to be heated on coil elements, but later the heating elements were built inside of them.

Early on, heating elements were only used by the wealthy and by lucrative businesses. During the economic boom of post-World War II, though, electrical appliances with heater elements flooded the market and became commonplace in the home. Three typical heating appliances of the time were: bar heaters, electric radiators and portable oil-filled radiators. In the 1950s, radiant bar heating was incredibly popular because models were portable and could be plugged in anywhere. In addition, they provided heat very quickly. However, while they were less dangerous than fuel burning heaters, they did not have enough protective shielding, and exposed users to the possibility of burns. Also, if they were knocked over or someone draped clothes over them, they could easily start fires. Today, some people still use bar heaters, though they must meet much higher safety standards than they did in the 1950s. From the bar heater were born many other wire element heaters, such as the infrared heaters we use today.

Into the 1960s, as homeowners began to rely on home heating more and more, prices skyrocketed. As a way to bring heating costs down, manufacturers in the U.K. invented a new heater type, the storage heater. Storage heaters worked using electric heating elements that heated thermal bricks inside the thermal body overnight. Then, during the day, users could release the heat as needed without generating more electricity. In the 1970s, governments around the world faced an oil crisis, and so turned to more electricity heating elements. Eventually, storage heaters went out of style because they had to be manually operated and required a lot of predictive action by users. In addition, they weren’t energy efficient. Once the 1990s hit, people began to swap out their industrial and home heating systems for more modern electric radiators, which are easier to control, faster heating and more energy efficient. Another innovation of the 90s was the screen-printing of metal-ceramic tracks onto ceramic insulated metal. Heating elements created this way are widely used in domestic appliances like kettles.

The digital growth of the 21st century has allowed heating elements and the systems they serve to become much more sensitive, intuitive and energy efficient. Heating element assemblies now include elements like LED screens, Wi-Fi control, smart meters, digital keypads and digital programmers for temperature heating schedules. Features like these allow modern heating elements to work with extreme precision and complexity. Another distinction of 21st century heating elements is the fact that they rely much less heavily on fossil fuels, as sustainability, energy efficiency and health have become much more important.

Characteristics

Heating elements are responsible for converting electricity into heat. For the translation of energy, they follow the theory of Joule Heating. When electric energy goes through an element, it lands on a high-capacity resistance. Resistance converts to electrical energy, which converts to heat energy. The amount of heat energy produced correlates to how much the material resists the applied electrical current. Measurement of the resistivity of a given length of element wire is based on resistance per length and cross-sectional area. Engineers measure this in Ohms per meter. In turn, they use ohms to calculate the element’s kilowatt (kw) load. The kw load represents how much electrical power the heating element carries.

Heating Element Types

Heating element varieties used in industrial, commercial and consumer applications include: immersion, quartz, flexible, infrared, wire, ceramic, electric, metal-based and composite heating elements, among many others.

Immersion Heating Element

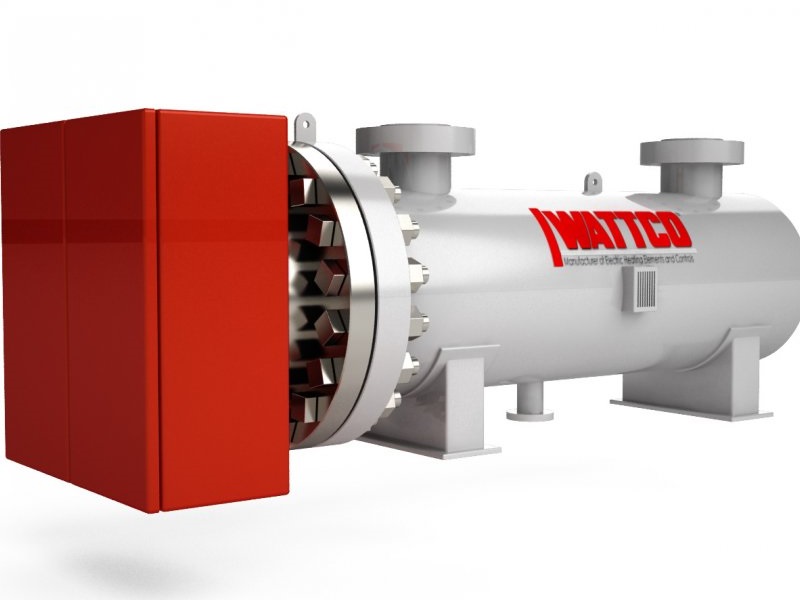

Immersion heating elements are used to heat gases and liquids; they have the special ability to be immersed in the materials they heat without malfunctioning. Immersion heaters are further characterized by their fast, efficient and cost-effective heating solutions. Types of materials they typically heat include plating baths, mild acids, oils, water, salts, air, and chemical solutions. Immersion heating elements are primarily with systems like: process systems, boilers, water heaters, heat transfer systems, oil heaters, and storage tanks.

Quartz Heating Element

Quartz heating elements convert electrical currents into infrared rays by running them through special resistors. In doing so, they provide rapid heating. These fast process speeds make them very popular for use with industrial applications like film curing, thermoforming, powder coatings, adhesive sealing, and paint drying, as well as zone control applications in automotive, print, petrochemical, textile, glass and electronic industries.

Flexible Heating Element

Flexible heating elements are able to bond to a variety of compounds and shapes and provide direct heating. This versatility is possible because they are very thin and bendable.

Infrared Heating Element

Infrared heating elements emit heat in the form of infrared waves, which are a type of electromagnetic radiation known for transferring heat efficiently. Infrared heating elements are used in conjunction with radiating heaters like duct, immersion, and tubular heaters, which heat air or liquid on the large scale. They support industrial ovens, pressure vessel heating, storage tank heating, boilers, water treatment plants, steam generation and more.

Wire Heating Element

Commonly, heating elements, whatever their type, are found in the form of coils or wires. In fact, wire heating elements are among the most widely used heating elements for industrial and commercial drying. To make them, manufacturers map them out with wire diagrams. They are found in surface treatment heaters, kilns, and many other dryers.

Ceramic Heating Element

Another type of heating element, the ceramic heating element, is utilized in convection heating; ceramic elements are built into space heaters, furnaces and semiconductors. There are several types of ceramic heating elements, including molybdenum disilicide and PTC.

Molybdenum Disilicide Element

Molybdenum Disilicide is a material that shows the characteristics of both a metal and ceramic. With an extremely high melting point, (to be precise, 3690 º F), it is considered ideal for a number of high-capacity heating elements, used across industries, including the glass manufacturing.

PTC

PTC, which extends to positive thermal coefficient for resistance, is a high-profile ceramic material that is utilized in automotive rear-window defrost heaters, space heaters and expensive hair dryers. There are also available polymer based PTC ceramics that are used in many purpose-built heaters. These elements increase the heating as their resistance is amplified. Controlling the heating of these elements is simple, that is because they are the selection for self-regulating electric heaters.

Electric Heating Element

Electric heating elements are quite prevalent as well, especially in the service of industrial electric heaters.

Cartridge Heater

Cartridge heaters supply localized heat to equipment parts in metal fabricating, foam fabricating, plastic fabricating, food processing and packaging.

Metal-based Heating Elements

As the name suggests, metal-based heater bodies are composed primarily of metals. Because metal is generally such a good conductor of heat and electricity, metal-based elements make one of the most effective heating elements. They are used in everyday and industrial appliances alike. They can be classified in many subtypes, including nichrome-based heating elements and resistance element wire based heating elements.

Nichrome Heating Element

A large number of electric heaters have elements made of nichrome, which is an alloy made up primarily of nickel and chrome. Nichrome based heaters use alloys of 80% nickel and 20% chromium.

Resistance Wire Heating Element

Some metal-based parts are composed by a set of high resistant wires and ribbons. These wires can be sometimes straight or coiled, as per the design and heating capacity of the appliance. These wires are used as resistance. The applications, in which you can find such provisioning, are toasters and handheld body massagers. Kanthal, nichrome and cupronickel are a few most used metals in the conception of resistance wires.

Coil Heater

Coil heaters, band heaters or strip heaters help extruding channels and hoppers maintain the plasticity of materials as they are being extruded.

Composite Heating Elements

Composite heating elements are heating elements made up of a mixture of metallic and ceramic materials. These heating elements are available in many types, including, among others, tubular elements, radioactive elements and removable ceramic core heating elements.

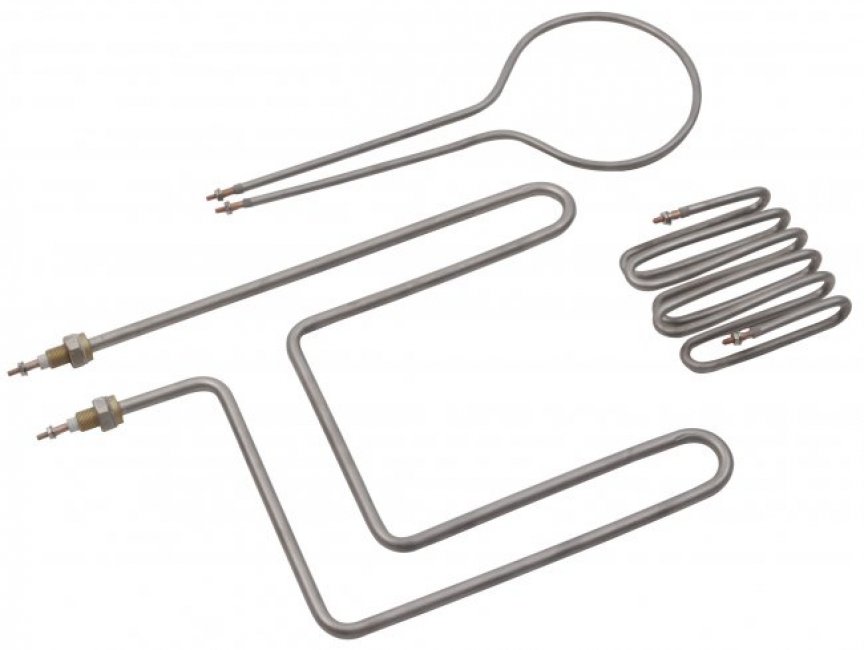

Tubular Heating Element

Tubular elements are basically metallic tubes that have a thin coil of nichrome, which heats up the application. Named for their tubular shape, tubular heating elements are found in ovens, dishwashers and more. They may be manipulated into a standard shape or they may be take on a custom shape for a specific application.

Radioactive Heating Element

Radioactive elements, also known as heat lamps, are high powered incandescent lamps that primarily radiate infrared waves, not visible light. Most often, they’re used in radiant space heaters and many types of food warmers. They come in two main styles: tubular and R40 reflector lamp. Reflector lamp heating elements come in a few main styles: gold coated, ruby red coated and clear.

- Gold coated lamps feature a deposited gold dichroic film on the inside. This reduces visible light and lets through the majority of the short and medium infrared waves. These are primarily used to heat people.

- Ruby coated lamps have the same function as gold coated lamps. They are much less expensive than gold coated lamps, but they permit a much stronger visible glare.

- Clear lamps have no coating, and are used primarily in industrial production processes.

Removable Ceramic Core Element

These heating elements are made up of coiled resistance wire threaded through one or more cylindrical ceramic segments that may or may not feature a center rod. They work when inserted into a metal tube or sheath that is sealed at one end. Because of this, users can replace or repair removable elements easily, without fear of breaking anything. Usually, they’re used to heat a fluid under pressure.

Carbon Fiber Composite Element

These heating elements are made up of a combination of carbon fiber and a resistive material like nickel, a thermoset like epoxy or a thermoplastic like PEEK. Carbon fiber composite elements are generally corrosion resistant, extreme temperature resistant and lightweight. They’re often used in aircraft de-icing, consumer heating and industrial heating.

Accessories

Various accessories are available to complement and enhance the functionality of heating elements in different applications. Wire and element holders, for instance, serve as support structures to securely hold the heating element in place, preventing it from moving or sagging during operation. Thermal switches, meanwhile, act as safety devices that monitor the temperature and cut off power to the heating element if it exceeds a certain threshold, preventing overheating and potential hazards. Additionally, manual connecting clips are used to establish electrical connections between the power source and the heating element, ensuring a reliable and safe power supply.

Pliers are helpful tools used for handling and shaping heating elements, especially during installation and maintenance. Braided wire is often utilized to improve the flexibility and durability of the electrical connections between the heating element and other components. Furthermore, silicone O-rings provide a watertight seal in applications where the heating element needs to be immersed in liquids. Bolts are used for securing heating elements to their mounting brackets or frames.

Adaptors and extension cords allow for compatibility between different types of heating elements and power sources or enable reaching power outlets at a distance. Power cords are essential for connecting heating elements to electrical sockets and ensuring a safe power supply. Finally, electrical boxes serve as protective enclosures, housing the electrical connections and ensuring the safety of the heating element’s operation.

Determining which accessories are needed depends on the specific heating element application and requirements. For instance, in industrial settings, where safety is paramount, thermal switches and silicone O-rings may be essential. Wire and element holders are crucial for securing the heating element in place, especially in appliances that are frequently moved or exposed to vibration. Pliers and braided wire become useful when dealing with heating elements of intricate designs or when a high level of precision is required during installation or repair.

To obtain these accessories, individuals can explore several options. Many heating element manufacturers or suppliers offer a range of compatible accessories for their products, making it convenient to find the appropriate components for a specific heating element model. Online retailers and specialized electrical or heating equipment stores are excellent sources to browse and purchase these accessories. Local hardware stores might also carry a selection of common heating element accessories for household applications. Consulting with heating element experts or professionals in the field can also provide valuable insights into the most suitable accessories for a particular heating element application.

Proper Care for Heating Elements

In order to achieve safe and effective operations, you must correctly pair your heating element and its application. A failure to do so has the potential to result in short circuiting, fires, product damage or equipment loss.

Most heaters tend to lose their heating capacity over time. When the performance of a heater declines, that simply means there is some issue with its heating element. So, from time to time, you will need to replace your heating element. Generally, manufacturers will offer purchasable or custom-made replacement element options, depending on customer needs. More often than not, this replacement process has a fairly quick turnaround time and is considered a part of a regular maintenance schedule. If a heating element goes out in an end-user item, like a hairdryer, however, it’s probably more economical to replace the whole item rather than its heating element.

Manufacturers may offer to install the replacement element, or you may do it yourself. For a step-by-step guide to testing and replacing an old heating element, keep reading. Our tips promote user safety; however, if you feel unsure, you should ask an expert to do the testing and replacement.

- First, perform a visual inspection. If you see any sign of discoloration, damage, or burning on the coil, then the element will need to be replaced. If you do not notice anything unusual during the initial assessment, then you can proceed.

- Calculate the resistance of the element. This is a mathematical exercise; you can use a calculator to find the resistance of the part. The simple formula for this calculation is: R = (V x V) ÷ P. In this equation, R stands for resistance, V for voltage, whereas P stands for the power that the element needs.

- Once you have the resistance, it is time to check the element using a metering tool – multimeter. Set the device to show resistance and choose an appropriate measuring scale for this. Make sure that the heater is not connected to the power supply. Now, measure the resistance of the element by touching the terminals of the heating elements with the leads of the multimeter.

- Match the resistance reading provided by the multimeter with the one that you calculated.

If there is a match, then there is no problem with the element. In this case, if you noticed any irregularity in the heating of your appliance lately, then there probably is some other issue with it. You need to get that checked by a repair service.

However, if the observed reading is higher or lower than what you calculated, then you will need to replace the element. You could get this done by a professional service or you could check out a video tutorial for the element replacement.

NOTE: If you are performing this test in a water heater, you will need to drain out all the water from the tank and allow it to dry out completely. You should also unplug the device and turn off the breaker panel. Once done, carefully remove the electric wires and open the tank to perform the test and replacement.

Standards

The manufacture and use of heating elements are subject to various standards to ensure safety, performance, and compliance with industry guidelines. In the United States, standards for heating elements are often set by organizations and government agencies such as Underwriters Laboratories (UL), American National Standards Institute (ANSI), and the National Fire Protection Association (NFPA). These standards are essential to promote consistent quality, prevent hazards, and protect consumers and workers from potential risks associated with heating elements.

The National Electrical Code (NFPA 70) is a critical standard regarding heating elements because it provides guidelines and requirements for electrical installations, including heating elements. This code is updated periodically to address emerging technologies and safety concerns, making it an important reference for electrical contractors, engineers, and other professionals in the industry. Adherence to the NFPA 70 ensures that heating elements are installed correctly, wired safely, and that all electrical components meet the necessary safety standards.

Using heating elements that do not meet the required standards can have severe consequences. Such non-compliant elements may pose safety risks, leading to electrical fires, electric shocks, or other hazardous incidents. Moreover, the use of non-standard heating elements might void warranties and insurance coverage, leaving users liable for any damages or accidents that may occur. Additionally, in commercial and industrial settings, using non-compliant heating elements may lead to legal issues and potential fines for violating safety regulations.

On the other hand, using heating elements that meet recognized standards offers numerous benefits. First and foremost, they ensure the safety of the equipment, the users, and the environment. Compliant elements have undergone rigorous testing and certification processes, ensuring that they function reliably and efficiently within their intended parameters. Meeting standards also facilitates interoperability and compatibility with other components and systems, reducing the risk of malfunctions and enhancing overall performance. Moreover, using compliant heating elements can lead to cost savings in the long run, as they tend to have longer lifespans and are less likely to require frequent replacements or repairs.

In conclusion, standards associated with the manufacture and use of heating elements are crucial for maintaining safety, quality, and efficiency. The National Electrical Code (NFPA 70) is a particularly important standard in the United States, outlining requirements for electrical installations, including heating elements. Using heating elements that comply with established standards ensures the protection of individuals and property while avoiding potential legal and financial consequences associated with non-compliance. Compliant elements offer reliability, longevity, and compatibility, making them a preferred choice for a wide range of heating applications.

How to Find the Right Manufacturer

To ensure you have the most productive outcome when purchasing heating elements from a heating element manufacturer, it is important to compare several companies using our directory of heating element manufacturers. There, each heating element manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each heating element business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple heating element businesses with the same form.

Check out our Electric Heaters website

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services