With critical applications in residential, commercial and industrial processes, heater elements are manufactured from a variety of materials and in many configurations. Heater elements are capable of providing heat from room temperature up to over 1300°F. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

Ulanet™ has 78 years of engineering and manufacturing experience in the production of cartridge, hermetically sealed, miniature, capsule, industrial thermostats, thermal time delay relays, immersion heaters, and numerous other heating elements.

At Hi-Heat Industries, we understand that every industrial application is unique, and our commitment to customization sets us apart from the competition. Alongside our standard product offerings, we provide various customization options to tailor the heating elements precisely to the client's specifications. These options include temperature controls, bonding methods, and private labeling.

Thermo Heating Elements is the world-wide leader in manufacturing flexible heating elements of the highest quality. Our products include polymer thick film heaters, silicone heaters, tubular heaters, optically clear heaters, ultraflex heaters, mica heaters, kapton heaters, and pantograph heaters.

Dalton Electric Heating Co., founded in 1921, is a manufacturer of Watt-Flex high performance cartridge heaters. The unique split sheath design expands in a bore for maximized heat transfer. Dalton also manufactures replacement vacuum diffusion pump heaters for nearly all domestic and foreign pumps.

More Heater Element Manufacturers

Heater elements are widely used, as most appliances that require heat to perform their processes use a heater element of one kind or another. In fact, ovens, clothes dryers, water heaters, electric furnaces and other industrial, commercial and consumer appliances use heater elements extensively.

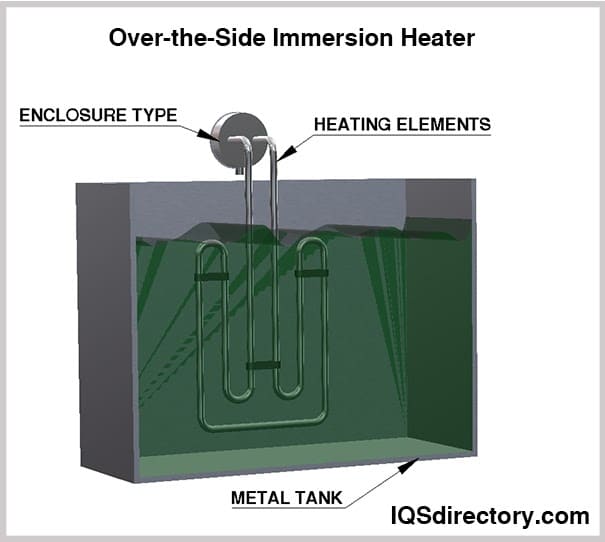

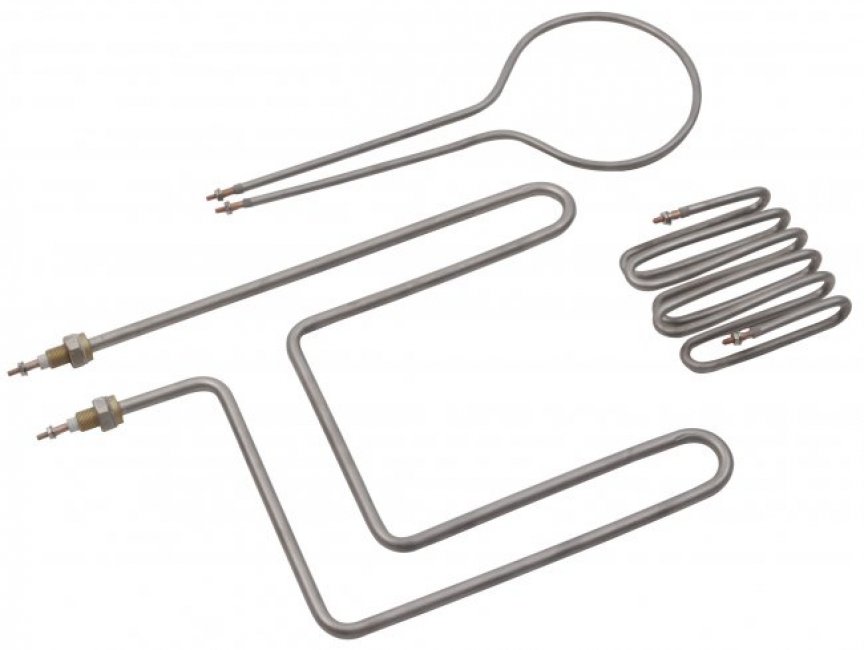

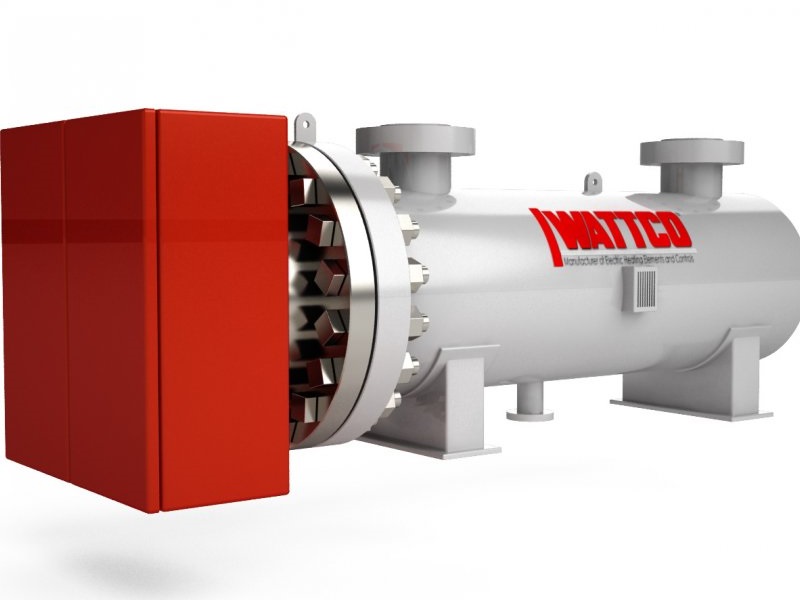

Industrial processes use heating elements in countless process heating applications in various types of industrial electric heaters. In addition, radiating types of heater elements such as immersion heater elements, quartz heater elements, and infrared heater elements are used to heat liquids or air in industrial ovens, storage tanks, pressure vessels, steam generators, boilers, water treatment facilities, and many other kinds of equipment. Some of the more common types of heater elements include tubular heater elements, ceramic heater elements, and heater coils.

Heater elements within electric heaters are mainly composed of three elements: an insulating core, a heat conductive coil wrapped around the insulation, and an encasing sheath made from stainless steel, aluminum, nickel or iron.

Insulating cores are necessary for most types of electric heaters to retain and absorb electrical energy so that it might be released as heat energy by surrounding coils or materials.

However, coiled wire heater elements, such as those used as household dryer heating elements, have no insulating core but transfer heat directly to the air through blown convection.

In higher heat applications, cores are responsible for converting electrical energy into heat energy and are heating elements' major component. Heater element cores are generally made from either NiChrome, a high resistance 80% nickel 20% chromium compound, or from a Positive Thermal Coefficient ceramic, which is a highly heat resistant barium titanate/lead titanate composite. Ceramics and NiChrome are by far the most common insulation materials, although various heater elements may use mineral insulation such as magnesium oxide, mica or fiberglass, depending on the heater's application requirements.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services