Heat generation devices, known as tubular heating elements, are defined by their tubular shape. The majority of variations are intended for use in touch-surface heating or radiant heating. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

Ulanet™ has 78 years of engineering and manufacturing experience in the production of cartridge, hermetically sealed, miniature, capsule, industrial thermostats, thermal time delay relays, immersion heaters, and numerous other heating elements.

At Hi-Heat Industries, we understand that every industrial application is unique, and our commitment to customization sets us apart from the competition. Alongside our standard product offerings, we provide various customization options to tailor the heating elements precisely to the client's specifications. These options include temperature controls, bonding methods, and private labeling.

Thermo Heating Elements is the world-wide leader in manufacturing flexible heating elements of the highest quality. Our products include polymer thick film heaters, silicone heaters, tubular heaters, optically clear heaters, ultraflex heaters, mica heaters, kapton heaters, and pantograph heaters.

Dalton Electric Heating Co., founded in 1921, is a manufacturer of Watt-Flex high performance cartridge heaters. The unique split sheath design expands in a bore for maximized heat transfer. Dalton also manufactures replacement vacuum diffusion pump heaters for nearly all domestic and foreign pumps.

More Tubular Heating Element Manufacturers

What are Tubular Heating Elements?

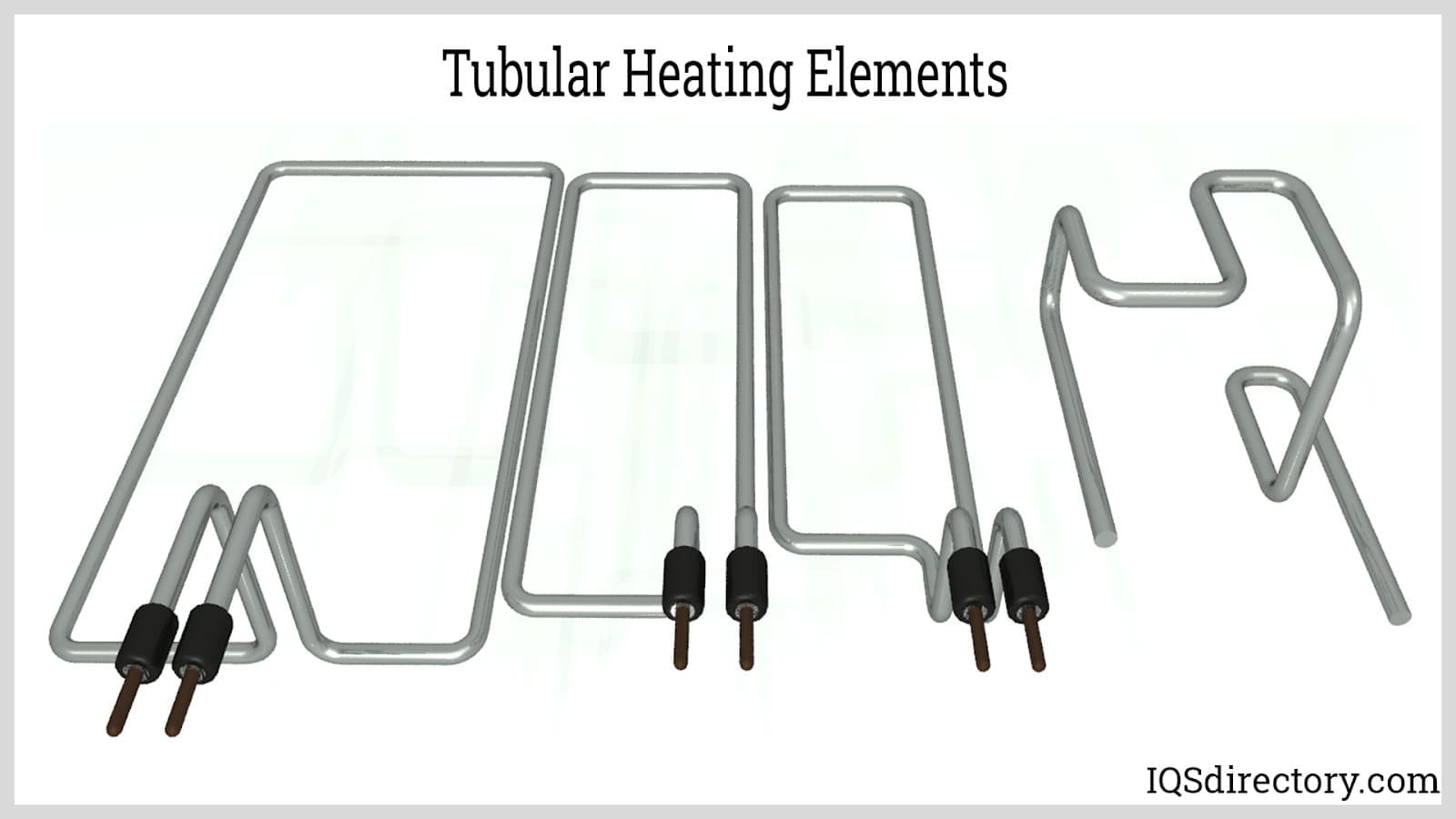

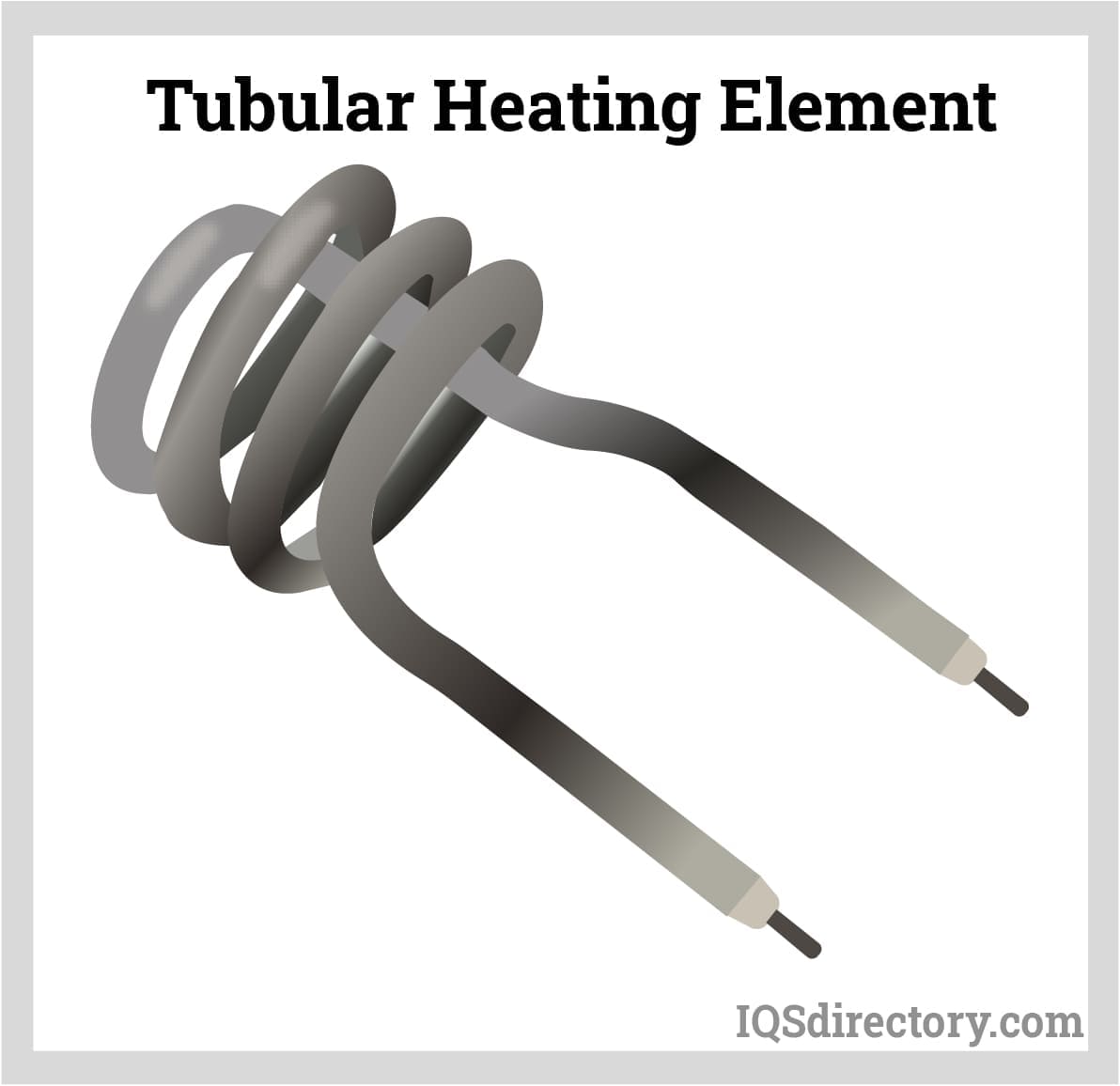

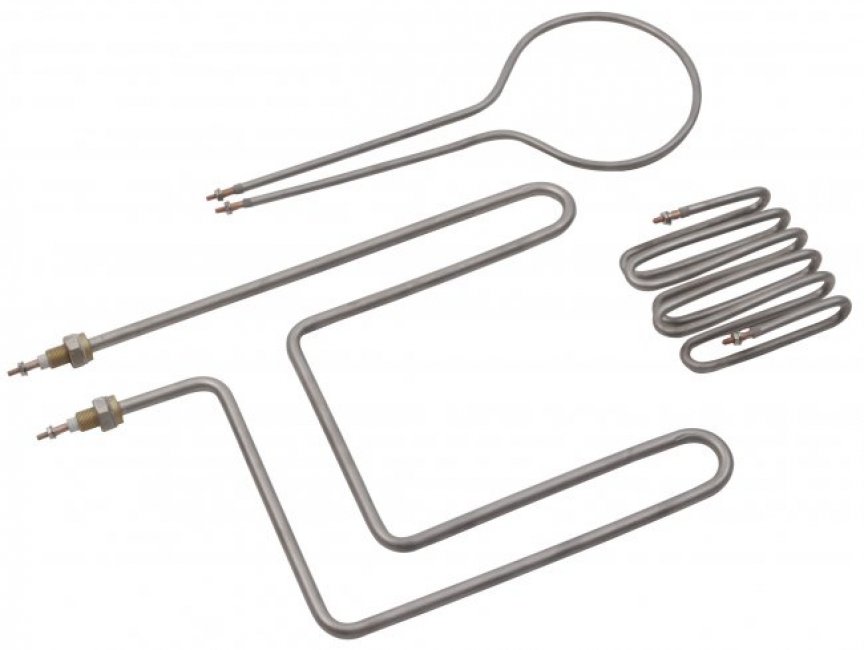

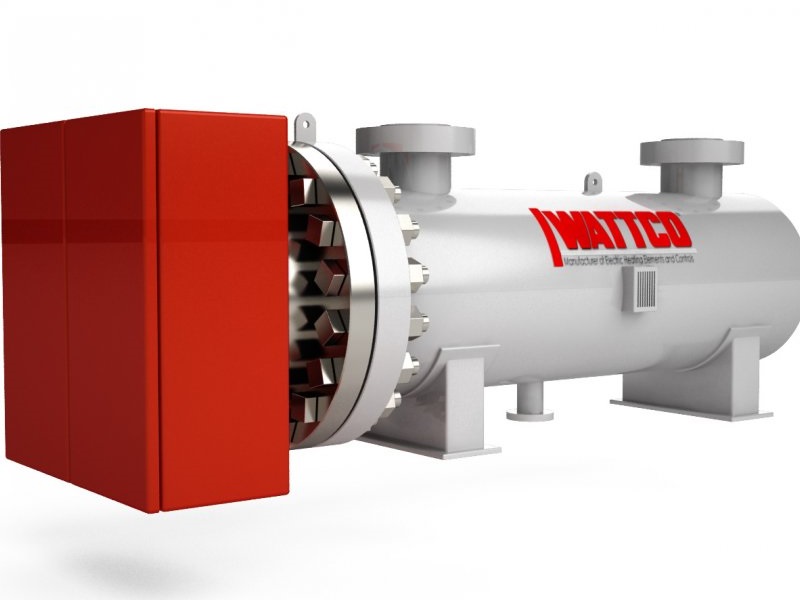

Tubular heating elements are a widely-used type of heating element that may be bent into standard or unique shapes to match a specific purpose.

The popularity of tubular heaters is largely due to their adaptability. To heat liquids, air, gasses, and surfaces, tubular heating elements provide excellent heat transmission through conduction, convection, or radiation.

The majority of heater assemblies use tubular elements in a variety of shapes, including round, triangular, flat press, and shaped.

How Tubular Heating Elements Work

Electricity is converted into heat with the use of heating components. First, conductors are efficient electrical transporters. Insulators, on the other hand, make poor electricity transporters.

Resistors are a component of electronic circuits that regulate current flow. Although in varying degrees, conductors and insulators both offer resistance to electric currents that pass through them. Insulators provide a high level of resistance, while conductors provide a low level.

In other words, when electricity passes through a resistor, it produces heat energy, which is how it functions. But not just resistors carry out this function. When applying enough electrical force to a wire, it will become hot even if it is very thin.

Incandescent bulbs (old-fashioned, bulb-shaped lights) operate on this fundamental principle. A filament is an extremely small coil of wire that is located inside the glass bulb. It creates light by creating heat when enough power goes through it since it flashes white hot and extremely brightly.

Heating elements thus offer a reliable electrical component that emits heat when a strong electric current passes through it.

Tubular Heating Element Design Considerations

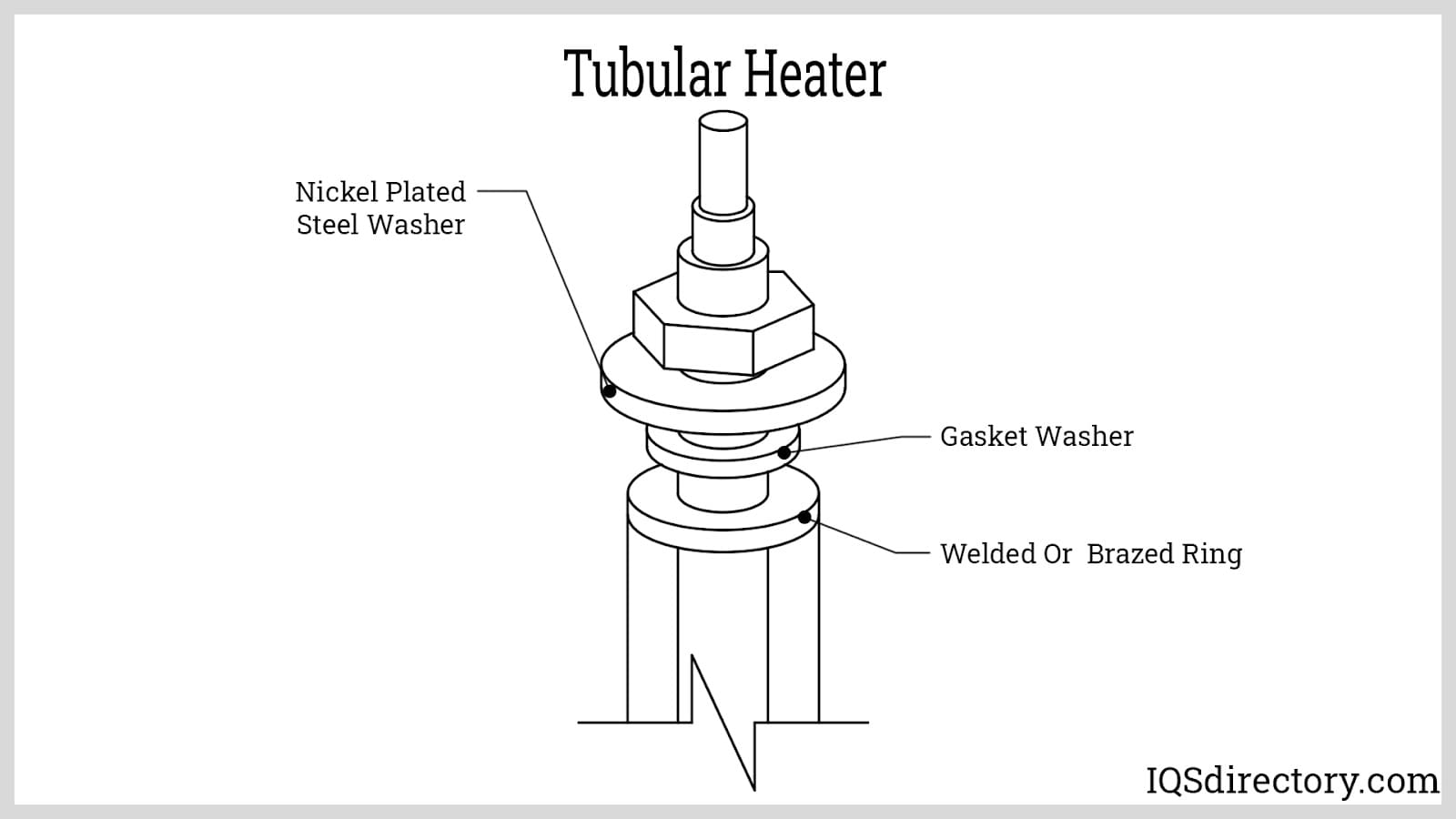

A tubular heater's composition and matching with other components need to be carefully considered in order to guarantee performance optimization and safety. For instance, explosion-resistant tube heaters are frequently employed to deliver heat close to explosive objects. This makes sure that the heating element won't make the issue worse in the event of an unintentional ignition during heating. Other controls and safety features, such as independent timing controls, overheat protection, internal temperature sensors, and other security measures, can also be included.

To increase heat generation capacity and prevent unintentional contact with dangers like leaking oils or grease, tubular heaters used in ovens are frequently insulated with a ceramic substance like silicon carbide. As a result, there are fewer chances of inadvertent ignition.

Fluoropolymers, other metals like iron and nickel alloys, polyimides, and even synthetic rubber are common insulation materials. Tubular heating elements can be used in a wider variety of applications than most other heating element variations due to the versatility of tubular heaters and the extensive customization choices accessible to their customers.

Applications of Tubular Heaters

- Reflectors are frequently used in tubular heaters for radiant heating in order to focus heat energy on the area that needs to be heated. Applications involving warming, drying, and curing work well with this. Watt density should be reduced by 20% to 30% compared to air heating since the main method of heat transfer when utilizing heaters in a vacuum is radiation. Vacuum feedthrough setups frequently use heaters with an aluminum or Inconel sheath.

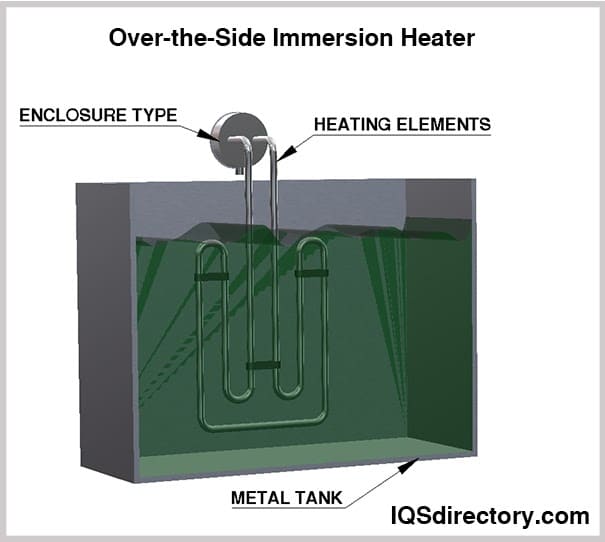

- They can be used as immersion heaters and heat sources that transfer heat directly or through the air. Tubular heaters are widely used in business, industry, and consumer items because of their adaptability. Although not all coil heaters are tubular, tubular heaters are sometimes referred to as coil heaters.

- Consumer, business, and industrial ovens and dryers, dishwashing machines, space heaters, and a wide range of other devices and appliances all use tubular heating coils. To increase their ability to generate heat and to shield the heating element from dangers, they are occasionally covered with ceramic insulation. Typically, a protective covering and an interior conductive substance make up tubular heating components. Nickel, steel, aluminum, copper, brass, and other metals that are both electrically and thermally conductive are a few of these materials.

- When it comes to heating water, oil, and grease, a number of businesses, from retail food to residential buildings, use copper-sheathed tube heaters. On the other hand, the stainless steel type is perfect for use in commercial applications that call for the use of powerful acids and bases. In the most corrosive situations, titanium sheaths are employed.

Choosing the Proper Tubular Heating Element Supplier

To ensure you have the most productive outcome when purchasing tubular heating elements from a tubular heating element supplier, it is important to compare several companies using our directory of tubular heating element suppliers. Each tubular heating element supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each tubular heating element business website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple tubular heating element companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services