Due to their reliable and efficient heating capabilities, silicone heating elements have been widely used in various industries. In this article, we will delve into various applications of silicone heating elements and how to determine the proper type of silicone heating element for one’s use. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

Ulanet™ has 78 years of engineering and manufacturing experience in the production of cartridge, hermetically sealed, miniature, capsule, industrial thermostats, thermal time delay relays, immersion heaters, and numerous other heating elements.

At Hi-Heat Industries, we understand that every industrial application is unique, and our commitment to customization sets us apart from the competition. Alongside our standard product offerings, we provide various customization options to tailor the heating elements precisely to the client's specifications. These options include temperature controls, bonding methods, and private labeling.

Thermo Heating Elements is the world-wide leader in manufacturing flexible heating elements of the highest quality. Our products include polymer thick film heaters, silicone heaters, tubular heaters, optically clear heaters, ultraflex heaters, mica heaters, kapton heaters, and pantograph heaters.

Dalton Electric Heating Co., founded in 1921, is a manufacturer of Watt-Flex high performance cartridge heaters. The unique split sheath design expands in a bore for maximized heat transfer. Dalton also manufactures replacement vacuum diffusion pump heaters for nearly all domestic and foreign pumps.

More Silicone Heating Element Manufacturers

Applications of Silicone Heating Elements

In the food industry, they are utilized in applications such as food warming cabinets, chocolate-tempering machines, and ovens, ensuring precise temperature control and maintaining product quality. Medical and healthcare sectors also rely on silicone heating elements in warming blankets, patient warming systems, and incubators, providing controlled and regulated heating for patient comfort and optimal conditions for biological samples. The aerospace and defense industry additionally benefits from silicone heating elements in de-icing systems, cabin heating, and temperature control in aircraft and spacecraft, where their lightweight and efficient heating capabilities are valuable.

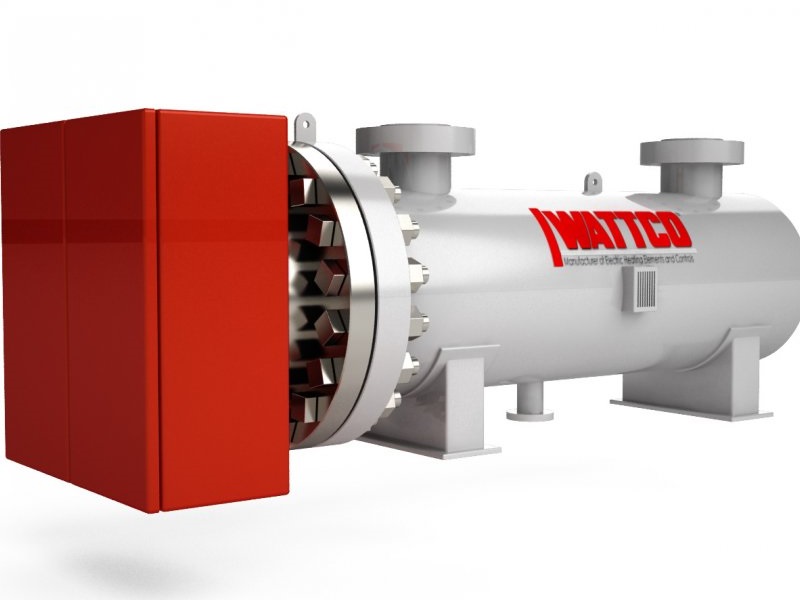

Automotive applications of silicone heating elements include seat heaters, rear window defrosters, and heated mirrors, enhancing passenger comfort, visibility, and safety. In the industrial sector, these elements are employed in processes such as curing coatings, heating molds, and thermal bonding, enabling precise and consistent heating for high-quality production outputs. Semiconductor and electronics industries utilize silicone heating elements in wafer processing equipment, thermal chambers, and testing systems to maintain specific temperature ranges during manufacturing processes, ensuring reliable semiconductor production.

Moreover, silicone heating elements are also used in applications like 3D printing, packaging equipment, laboratory instruments, and environmental chambers, where controlled and efficient heating is crucial. Their adaptability, reliability, and precise temperature control make them an ideal choice in industries where consistent and efficient heating is required.

These are just a few examples of the wide range of applications where silicone heating elements are employed. Their versatility, reliability, and efficiency make them a preferred heating solution across industries, providing precise heating control, enhancing productivity, and ensuring optimal performance in various applications. Manufacturers continue to innovate and develop specialized silicone heating elements tailored to the unique needs of different industries, further expanding their range of applications.

Choosing Silicone Heating Elements

Determining the proper type of silicone heating element for a specific application requires careful consideration of several factors. To begin with, the required heating specifications must be assessed, including the desired temperature range, heating rate, and uniformity across the surface. This helps when selecting the appropriate watt density, which refers to the power applied per unit area. Higher watt density elements are suitable for rapid heating, while lower watt density elements provide more gentle and uniform heating.

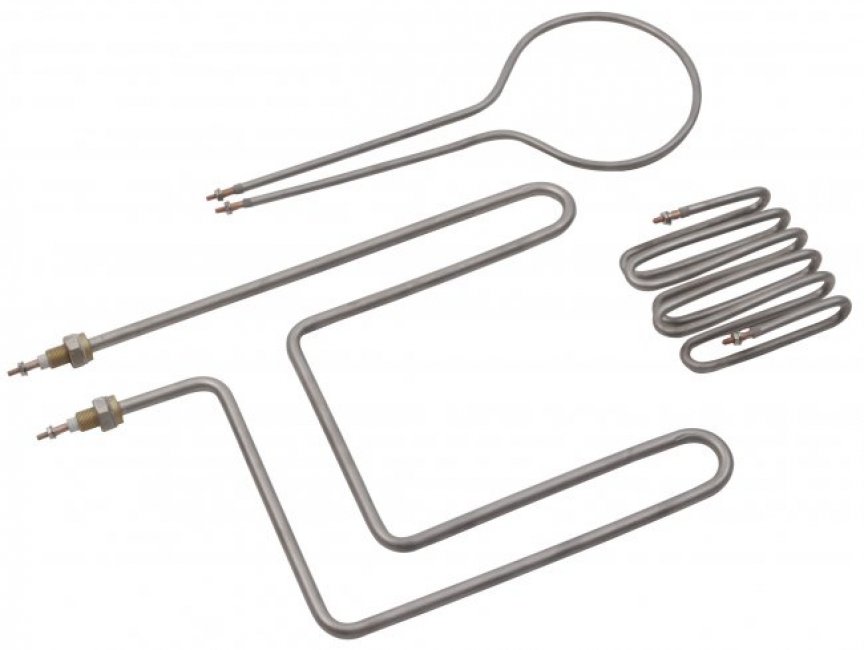

Next, the physical characteristics of the target surface or object must be taken into account. Factors such as size, shape, and material composition influence the design and dimensions of the heating element. Customization options like flexible pads, sheets, or molded elements ensure optimal coverage and fit.

Additionally, environmental considerations play a role in selecting the proper type of silicone heating element. Factors like moisture exposure, chemical resistance, and temperature extremes influence the choice of materials, insulation techniques, and protective coatings. Manufacturers offer a range of options to address specific environmental requirements and ensure the longevity and performance of the heating element.

Furthermore, electrical considerations are crucial when determining the appropriate silicone heating element. Factors such as voltage, power supply compatibility, and electrical safety standards need to be considered. Manufacturers provide guidance on these electrical specifications to ensure proper installation, operation, and compliance with industry regulations.

Finally, it is essential to consult with experienced heating element suppliers or manufacturers who can provide expert advice and assistance in selecting the optimal type of silicone heating element for the specific application. They have the knowledge and expertise to understand the heating requirements, recommend suitable designs, and provide customized solutions that meet the application's unique needs.

By considering these factors and seeking professional guidance, businesses can determine the proper type of silicone heating element that best aligns with their heating requirements, environmental conditions, and electrical considerations, and ensures efficient and reliable performance.

Advantages of Using Silicone Heating Elements

Silicone heating elements offer advantages that make them a preferred choice over alternative heating solutions in various applications. One of the key advantages is the flexibility and conformability of silicone heating elements. They can be easily shaped and molded to fit complex surfaces or objects, ensuring optimal heat transfer and coverage. This flexibility allows for greater design freedom and versatility in applications where heating elements need to be customized to specific shapes or sizes.

Another significant advantage of silicone heating elements is their rapid and uniform heating capabilities. They have excellent thermal conductivity, enabling them to heat up quickly and distribute heat evenly across their surface. This uniform heating helps in achieving consistent and reliable results, reducing hot spots and ensuring the desired temperature is maintained throughout the heating process.

Energy efficiency is another notable benefit of silicone heating elements. They have low thermal mass, which means they heat up and cool down quickly, resulting in reduced energy consumption. Silicone heating elements also offer excellent insulation properties, minimizing heat loss and maximizing heat transfer efficiency. This energy efficiency contributes to cost savings and environmentally friendly operations.

Silicone heating elements are highly resistant to moisture and chemicals. They can withstand exposure to harsh environments, making them suitable for applications where moisture or chemical exposure is a concern. This resistance enhances the longevity and durability of silicone heating elements, allowing them to maintain their performance even in challenging conditions.

Ease of installation and maintenance is another advantage of silicone heating elements. They can be easily installed using various attachment methods, such as adhesive backing, fasteners, or clamps. Maintenance is minimal, typically requiring only routine inspections to ensure proper functioning. Additionally, silicone heating elements offer precise temperature control capabilities, allowing for accurate regulation of heating processes, which is crucial in applications requiring specific temperature ranges.

Overall, the benefits and advantages of using silicone heating elements make them a preferred choice in numerous applications. Their flexibility, rapid and uniform heating, energy efficiency, resistance to moisture and chemicals, longevity, and ease of installation and maintenance contribute to their widespread use across industries. Manufacturers continue to innovate and enhance the features and performance of silicone heating elements to meet the evolving needs of businesses in various sectors.

Silicone heating elements play a vital role in various industries, providing reliable and efficient heating solutions. Their applications span industrial processes, healthcare, food processing, automotive, aerospace, and more. By considering the specific requirements of their applications, businesses can determine the proper type of silicone heating element and leverage their versatility to enhance product performance, temperature control, and overall operational efficiency.

Choosing the Right Silicone Heating Element Manufacturers

To ensure the best result when purchasing silicone heating elements, compare several companies using our directory of heating element companies. Each heating element company has a business profile page highlighting areas of experience and capabilities. Each profile has a contact form to directly communicate with the company for more information or to request a quote. Review each company’s website using our patented website previewer to quickly learn each company’s specialty. Then, use our simple RFQ form to contact multiple silicone heating element manufacturers with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services