Infrared heaters frequently use quartz heating components, which offer a source of quick heating. Electrical currents are transformed into infrared rays by passing them through specially crafted resistors in quartz infrared heating elements. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

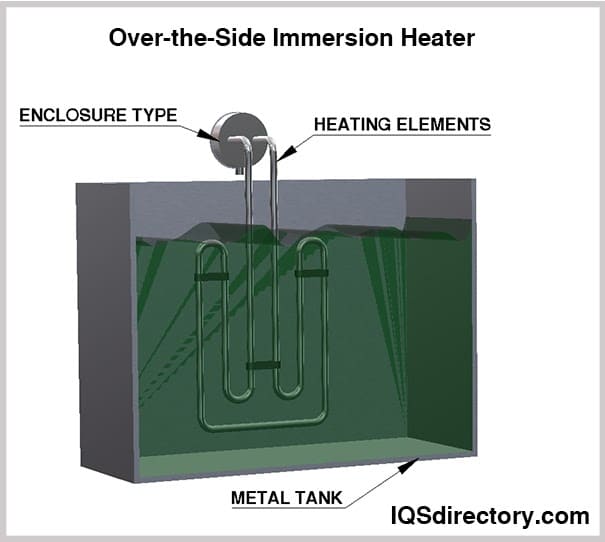

Ulanet™ has 78 years of engineering and manufacturing experience in the production of cartridge, hermetically sealed, miniature, capsule, industrial thermostats, thermal time delay relays, immersion heaters, and numerous other heating elements.

At Hi-Heat Industries, we understand that every industrial application is unique, and our commitment to customization sets us apart from the competition. Alongside our standard product offerings, we provide various customization options to tailor the heating elements precisely to the client's specifications. These options include temperature controls, bonding methods, and private labeling.

Thermo Heating Elements is the world-wide leader in manufacturing flexible heating elements of the highest quality. Our products include polymer thick film heaters, silicone heaters, tubular heaters, optically clear heaters, ultraflex heaters, mica heaters, kapton heaters, and pantograph heaters.

Dalton Electric Heating Co., founded in 1921, is a manufacturer of Watt-Flex high performance cartridge heaters. The unique split sheath design expands in a bore for maximized heat transfer. Dalton also manufactures replacement vacuum diffusion pump heaters for nearly all domestic and foreign pumps.

More Quartz Heating Element Manufacturers

What are Quartz Heating Elements?

Infrared radiation is used in radiant heating to warm surfaces directly. Infrared heat, a component of the electromagnetic spectrum with a frequency below visible light, is emitted and absorbed by all objects. More heat will radiate from hotter items. The majority of quartz heaters use this technology as their foundation.

The wavelength of these infrared rays varies depending on the use and the distance. Due to its high heat resistance and low heat absorption, quartz makes for an excellent heating element and electrical insulator.

How Quartz Heaters Work

Optical reflectors are used to focus this energy into precise patterns. Like light, infrared radiates from the heat source and disperses across a considerable area. This type of heating operates similarly to the sun, moving in parallel axes and even having the ability to traverse the vacuum of space. Because of this, quartz heating is unaffected by wind and effective at directly heating both people and things.

These heaters are appropriate for both indoor and outdoor heating, and because of their heat output, they are also quite successful at heating up large spaces.

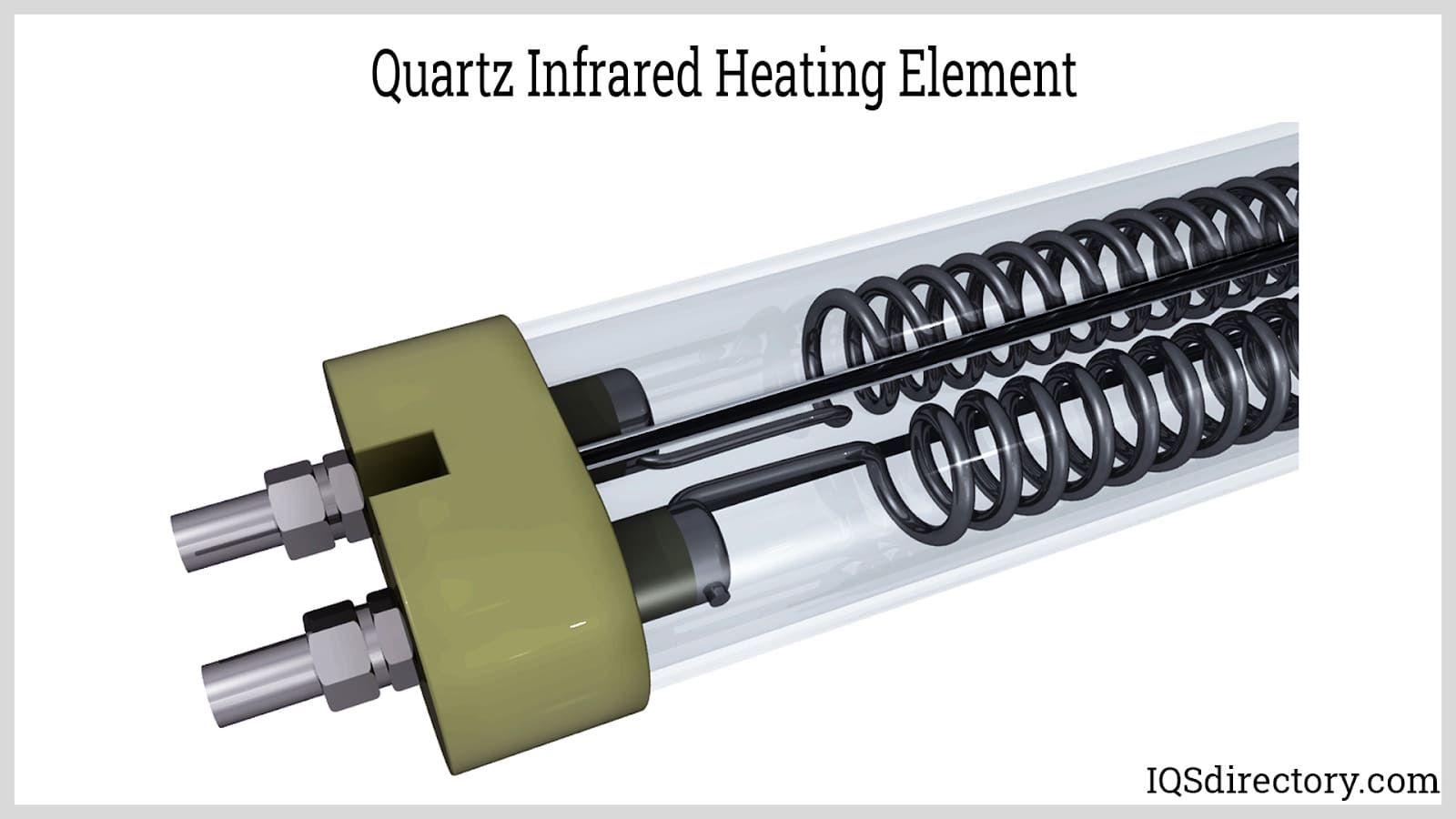

An infrared heater known as a quartz heater produces heat that is then released from the heater by a heating element that is housed inside a quartz tube. In order to obtain the proper degree of intensity to heat the particular material required, the heating element generates heat at the relevant wavelength.

The tube's dual functions are to safeguard the heating element and to prevent convective heat loss. The way quartz heating works is that once the heating element gets extremely hot, a quick buildup of heat occurs in the quartz tube. The heat is released from the tube after it reaches the proper temperature.

It has been established that the heat produced by this method is of the perfect wavelength for the human body. Due to the infrared spectrum falling almost entirely outside the air's absorption spectrum, the heat from the heater is directly absorbed by nearby persons and objects, while very little heat is absorbed by the air itself.

Types of Quartz Heater Elements

Medium-wavelength tube heaters: Typically consist of a quartz tube with a heating element inside of it. These can be installed in banks to make sizable heating arrays suitable for many drying applications.

Short wavelength tube heaters

Similar to medium wavelength tube heaters, short wavelength tube heaters have an element housed inside a quartz tube. The fact that these components are constructed of tungsten and the quartz tubes are sealed with a noble gas makes a difference. These heaters work wonders for applications involving powder coating and metal.

Quartz panel heaters

The heater has a face made of fused quartz, and there is an embedded heating element slightly below the surface. Compared to tube heaters, these higher mass heaters excel in producing a consistent energy output over a larger surface area.

Surface tube heaters

These heaters are made by encircling a quartz tube with a heating element. The user can benefit from both convection and IR heating by placing the heating element outside rather than within the quartz tube. These heaters work best in furnace situations where a predetermined temperature must be reached in both the surrounding air and the target object.

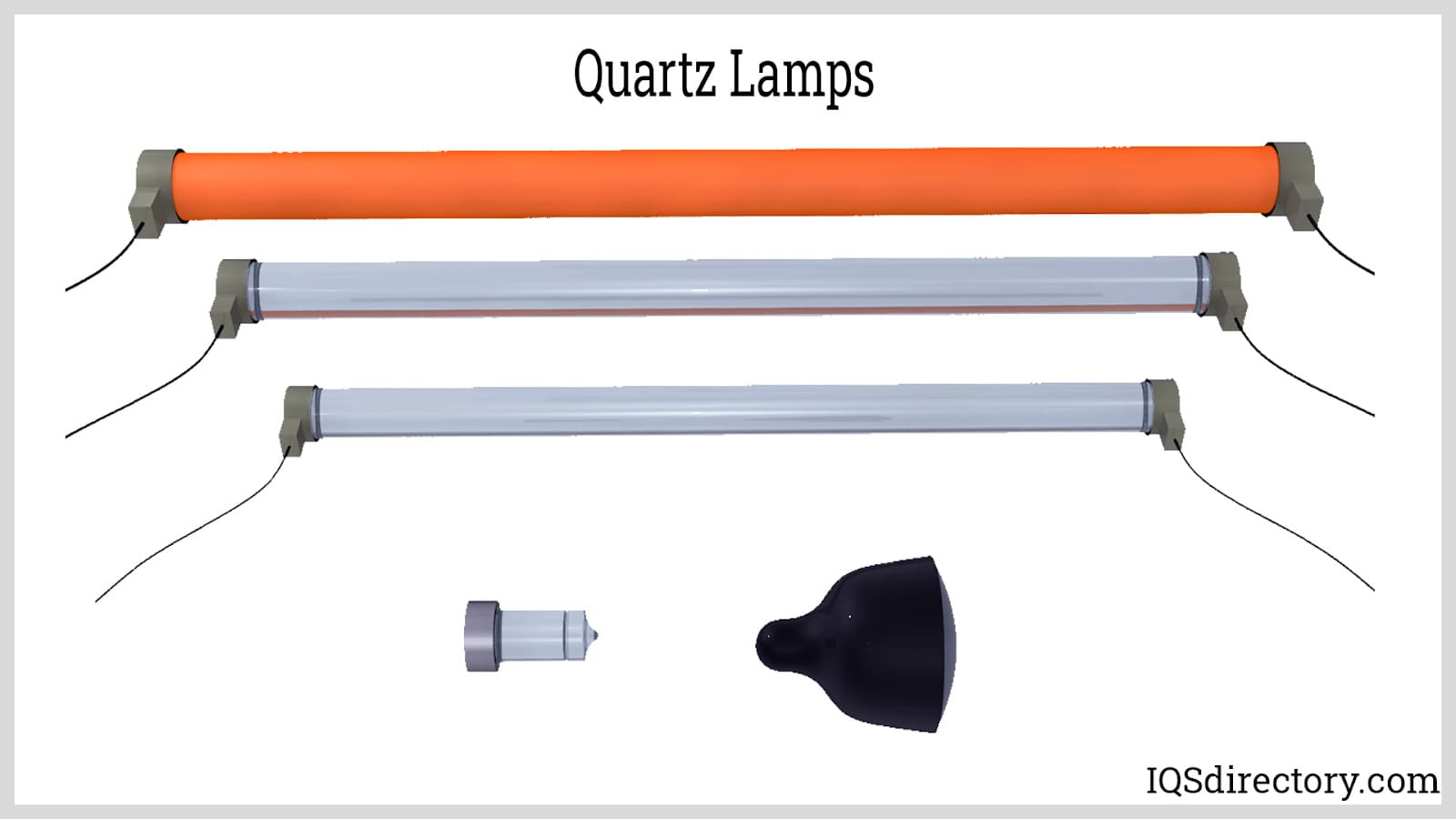

Quartz lamp

Quartz lamp components have an aluminum casing with a polished reflector. Quartz lamp elements in infrared heaters frequently provide usable infrared light at wavelengths less than five micrometers. In comparison to other open wire-coil sources, tungsten enclosed filaments can run at a temperature of about 2500° K and emit more short wavelength radiation. Quartz lamp elements have a very high watt density and are frequently utilized in high speed production operations.

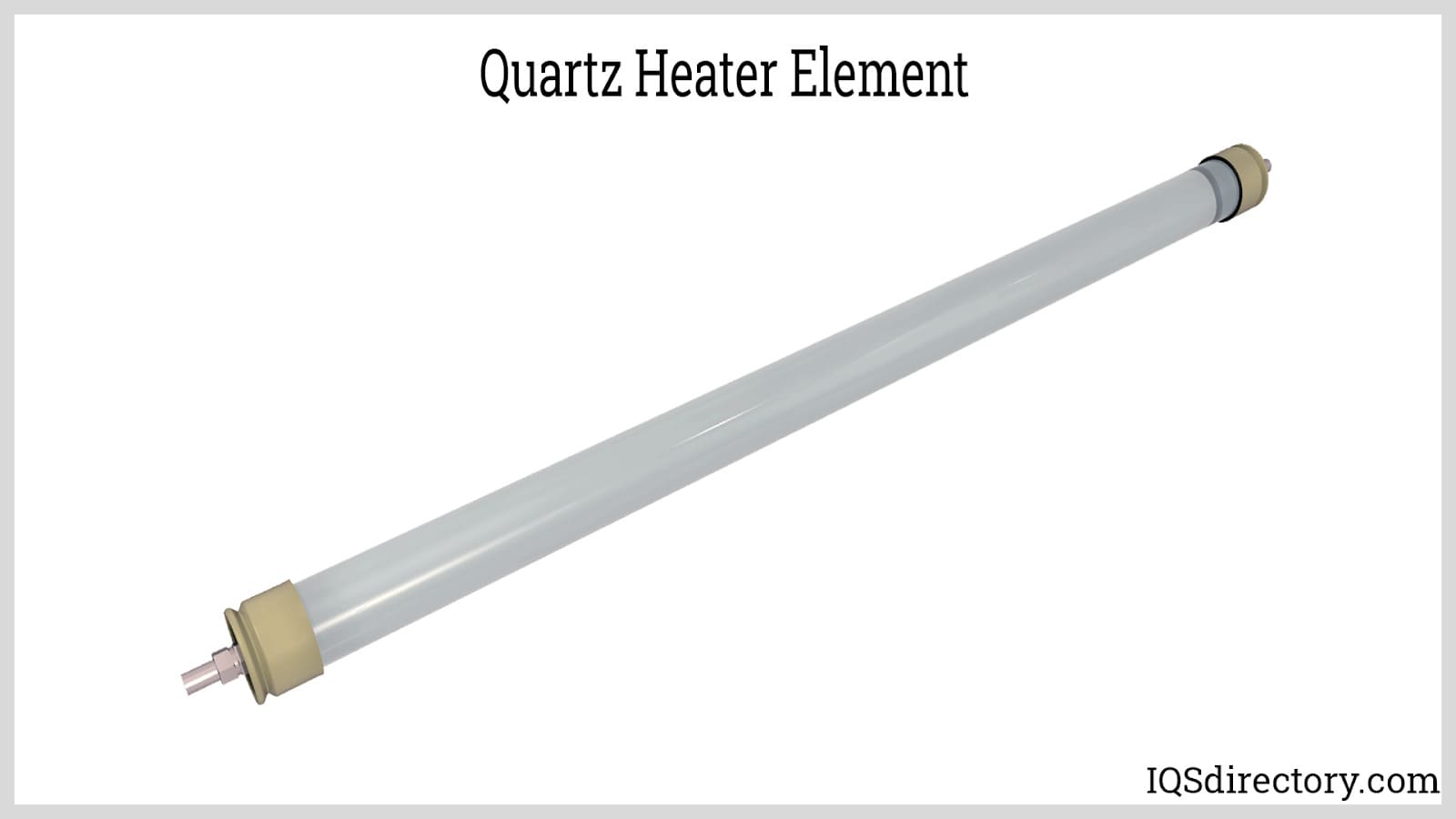

Quartz tube element

A quartz tube element is often built using a wrapped resistance coil that is passed through a number of parallel quartz tubes and then enclosed in a highly reflecting body, which is frequently constructed of aluminized steel. Quartz tube heating components are frequently utilized for the processing of heat-sensitive materials since they work best in radiant applications.

Choosing the Correct Quartz Heating Element Supplier

To ensure you have the most constructive outcome when purchasing quartz heating elements from a quartz heating element supplier, it is important to compare several companies using our directory of quartz heating element suppliers. Each quartz heating element supplier has a business profile page illustrating their areas of experience and capabilities, and a contact form to directly communicate with the supplier for more information or request a quote. Review each quartz heating element business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple quartz heating element suppliers with the same form.

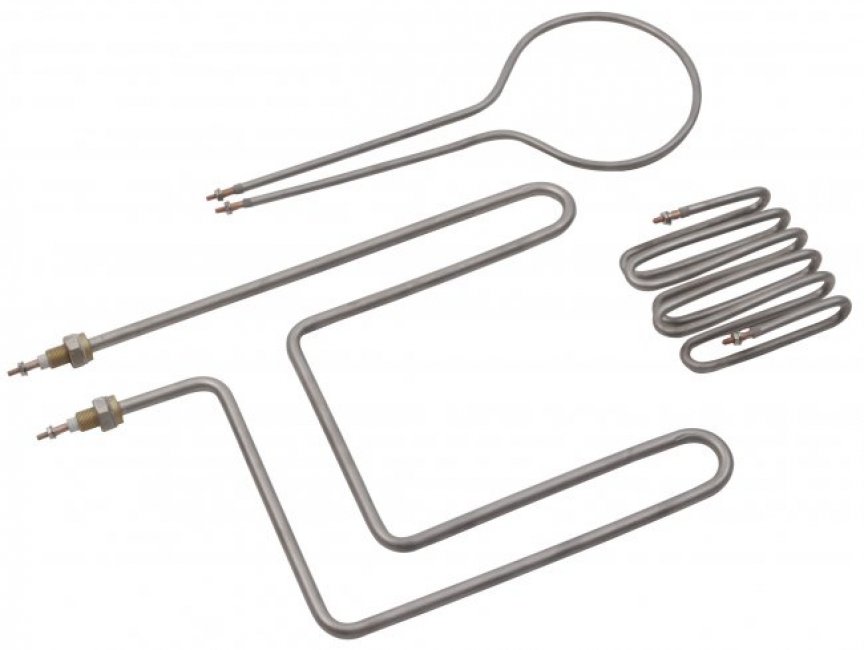

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services