Heating coils are useful equipment to produce heat. They are incorporated into commercial, consumer, and industrial appliances and equipment for various uses. Converting electricity to heat is how heating coils work. The most popular type of heating element is one with heating coils. In addition to numerous other uses, they produce heat in machinery and buildings. Usually constructed of metal or ceramic, an electrical current heats the coil. Space warmers, electric ovens, and hair dryers are common examples of this design. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

Ulanet™ has 78 years of engineering and manufacturing experience in the production of cartridge, hermetically sealed, miniature, capsule, industrial thermostats, thermal time delay relays, immersion heaters, and numerous other heating elements.

At Hi-Heat Industries, we understand that every industrial application is unique, and our commitment to customization sets us apart from the competition. Alongside our standard product offerings, we provide various customization options to tailor the heating elements precisely to the client's specifications. These options include temperature controls, bonding methods, and private labeling.

Thermo Heating Elements is the world-wide leader in manufacturing flexible heating elements of the highest quality. Our products include polymer thick film heaters, silicone heaters, tubular heaters, optically clear heaters, ultraflex heaters, mica heaters, kapton heaters, and pantograph heaters.

Dalton Electric Heating Co., founded in 1921, is a manufacturer of Watt-Flex high performance cartridge heaters. The unique split sheath design expands in a bore for maximized heat transfer. Dalton also manufactures replacement vacuum diffusion pump heaters for nearly all domestic and foreign pumps.

More Heating Coil Manufacturers

Types of Heating Coils

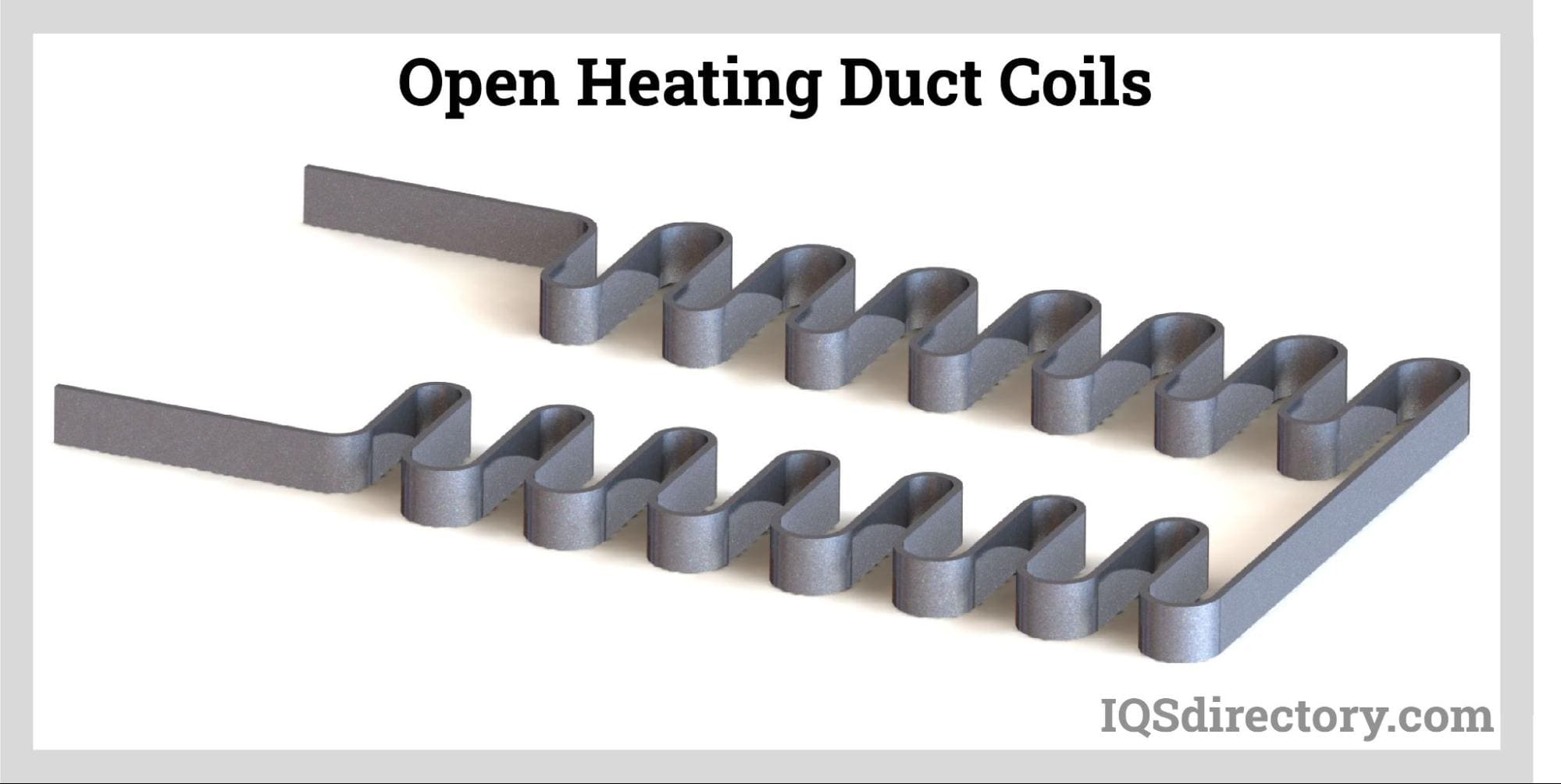

Electric heating coil elements come in two basic varieties: open and covered. Covered coils are used for direct heating, whereas open coils are used for indirect heating. Open coils are very effective and reasonably priced, although they are only appropriate for some applications.

Open Electric Heating Coils

The elements are exposed when coils are open. They have quick heating times since they are not required to supply heat through a protective covering. They require little maintenance and feature cheap, simple replacement parts. However, the exposed components are more susceptible to damage, which is a drawback.

Most open coil elements are found in:

- Space Heating

- Duct Heating

- Pipe Heating

- Metal Tubing

- Tank Heating

- Forced Air

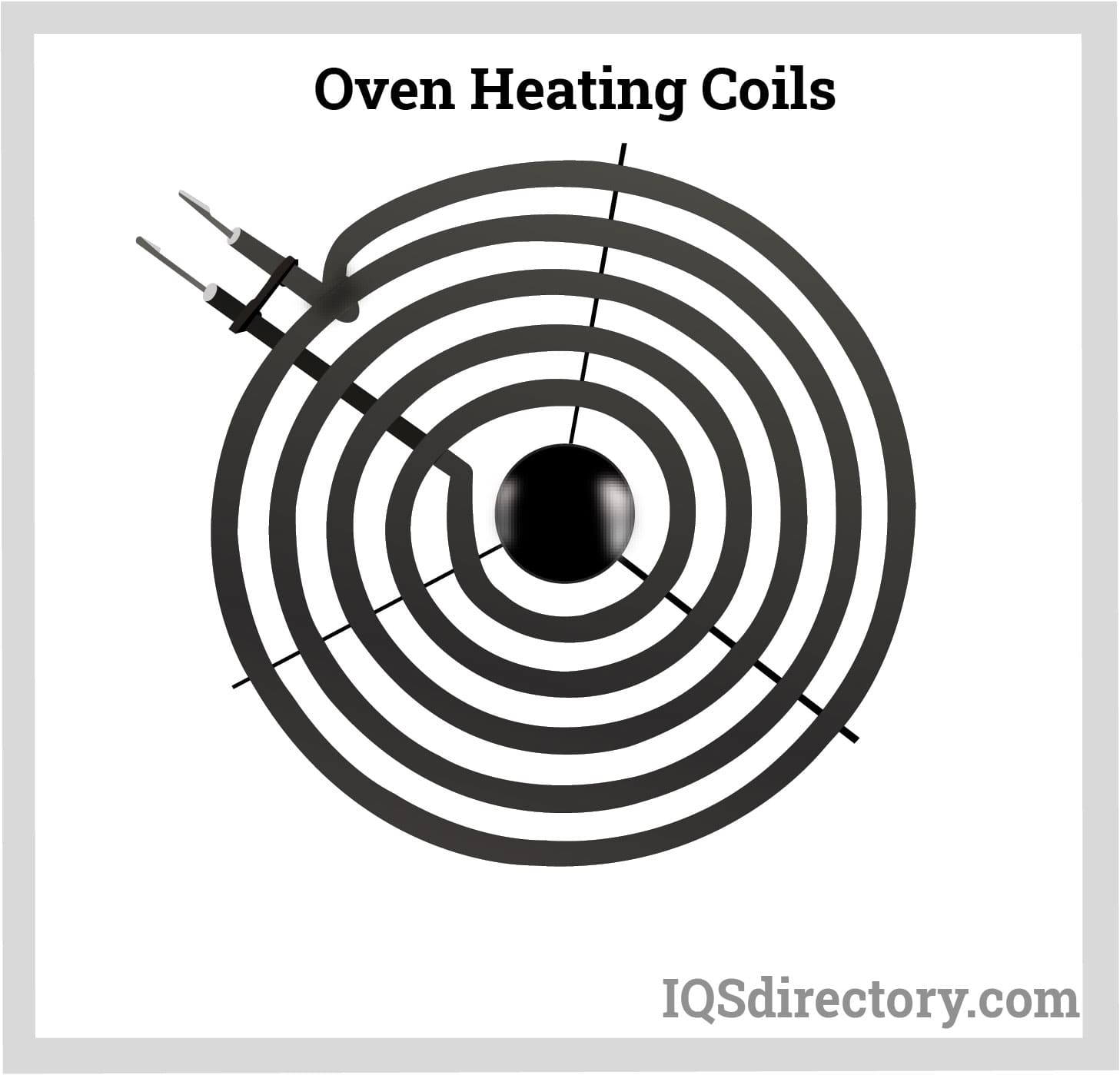

- Ovens

Applications of Heating Coils

The utilization of heating coils of various shapes, sizes, and heat generation capabilities can be found in space heaters, toasters, dishwashing machines, electric ovens, and many other appliances. Commercial ovens may come with ceramic-coated heat coils, which improve heat generation and shield the coil from potential risks such as dripping grease. Heating coils are a feature of many types of equipment used to remove moisture and generate heat, including industrial dryers, clothes dryers, hair dryers, and many others.

Some furnace setups use a mix of air blowers and heat coils to warm the air before distributing it through ducts. Additionally, some industrial machinery and procedures depend on heating coils.

Heating coils are used in the following machines:

- Metal-analysis tools

- Machines for plastic injection molding

- Speicher tanks

- Equipment for processing paper

- Oil reclamation tools

- Blow molding equipment

- Extruders

- Packaging supplies

- Bag-sealing equipment

- Hot stamping tools

- Labeling equipment

Design of Heating Coils

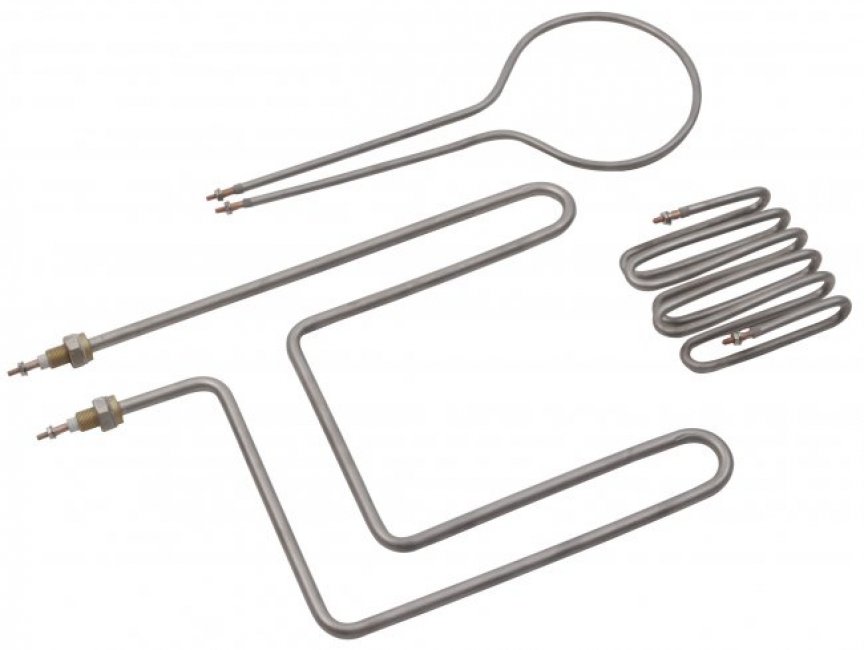

There are numerous sizes and types of coil heating elements. They can be bought in pre-made shapes or bent to a certain size or shape. They might be spherically wrapped, coiled, or circular. Different forms are appropriate in various contexts. In small places, spirally coiled elements are advantageous. Star-wrapped coils are used to create turbulence in pipes and ducts.

Many coil configurations are required due to the wide range of situations in which coil heating components are used. All coil heater applications, including holding tanks, extruders, blow molding machines, bag sealing, and hot metal forming punches, need a unique coil configuration.

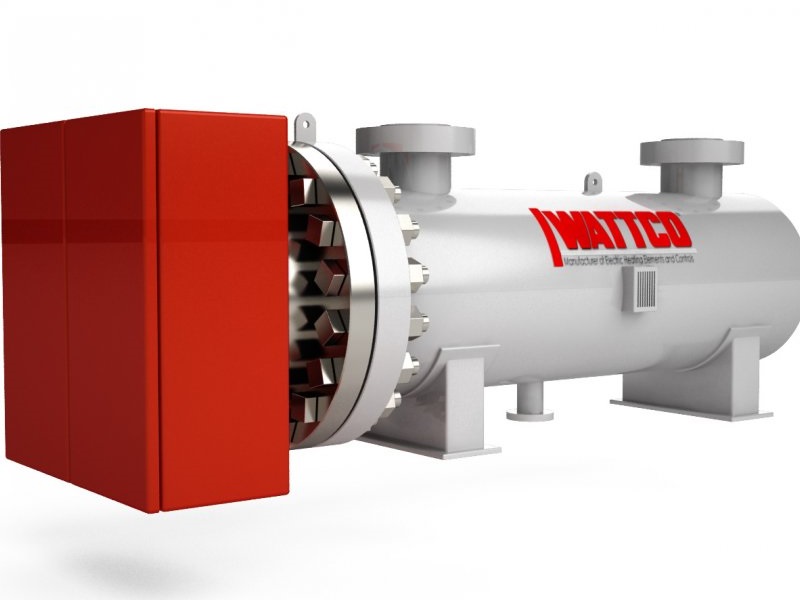

Coil heaters, which run on AC voltages, may reach temperatures of up to 1200° F and distribute a consistent heat pattern over a huge area. Ceramic, fiberglass, or mica insulation, can be manufactured of steel, brass, aluminum, copper, iron, or nickel and annealed. Some coil heaters are corrosion-resistant and can be submerged in heated liquids or utilized in cryogenic settings, depending on the metal. Coil heating elements must be properly matched with those applications to ensure the security and efficiency of such applications.

Advantages of Heating Coils

Flexible Shapes: Electric coil heaters may be shaped into practically any shape due to their remarkable ductility.

Rapid Temperature Change: The coil's low mass hastens heat transmission during heating and cooling.

Durability: These heaters are straightforward and quick to fix. Even with very little upkeep, they frequently have a very long lifespan.

Numerous Applications: Electric coil heaters are adaptable enough to be employed in various circumstances, including sub-freezing, gas heating, and liquid immersion.

Climatic Resilience: These heaters are widely used in the oil business because they provide just the appropriate amount of heat to facilitate pipe flow. Once installed, these heating systems' technological upgrades can survive severe climatic and meteorological circumstances.

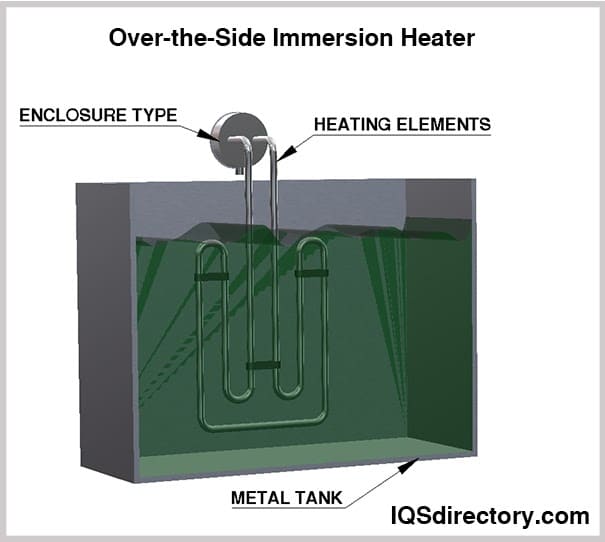

Safety: The immersion heater's controlling device is coupled to the heater so that the control box can be placed on an outer wall, increasing safety. This design eliminates the need to empty the tank if the controller or heater malfunctions. In addition, electrical heating appliances take up less space because they have fewer moving parts.

Choosing the Right Heating Coil Manufacturer

To ensure you have the most positive outcome when purchasing heating coils from a heating coil manufacturer, it is important to compare several companies using our directory of heating coil manufacturers. Each heating coil manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each heating coil business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple heating coil companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services